BRIEFLY ABOUT THE TECHNOLOGY

The goal of the technology is to ensure that products sealed this way remain fresh and safe to consume for a long period of time. Capsealing prevents the contents of the bottles from leaking, spilling, and foreign matter from entering the bottle, thus protecting the original condition of the product. The printing on the sealing liner helps identify the brand and makes it difficult to copy the product.

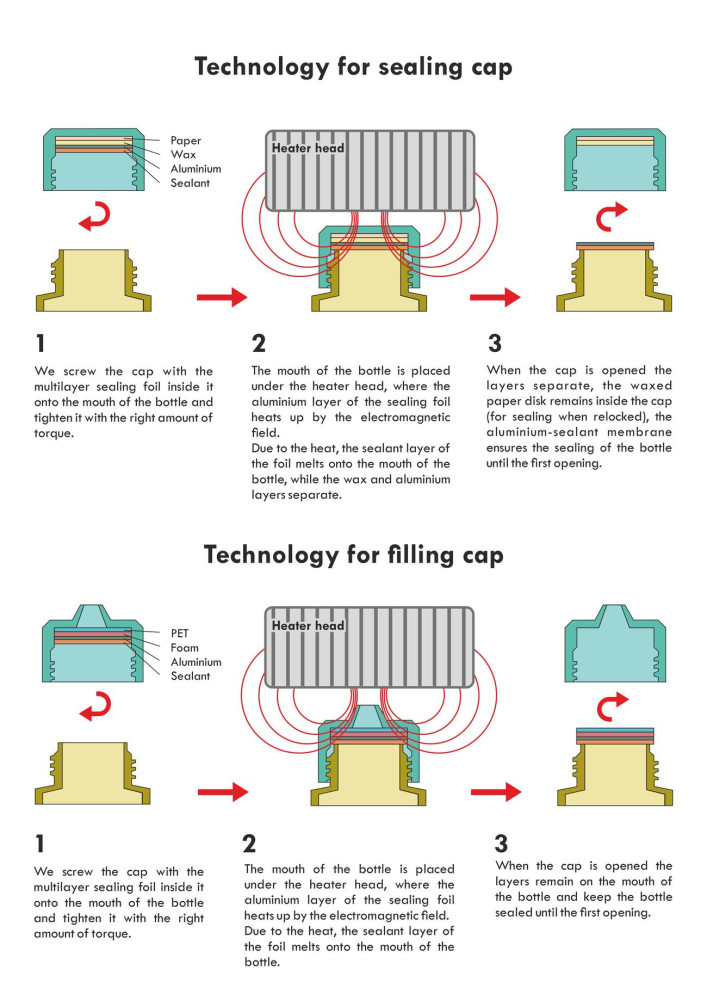

Induction capsealing is a fast, reliable, cost efficient technology suitable for the tamper-proof, hermetic sealing of bottles and other containers of most raw materials. The filled, prepared bottle with a cap that is fitted with a sealing liner is sealed under the heating head of the equipment as a result of the energy transferred by the alternating magnetic field.

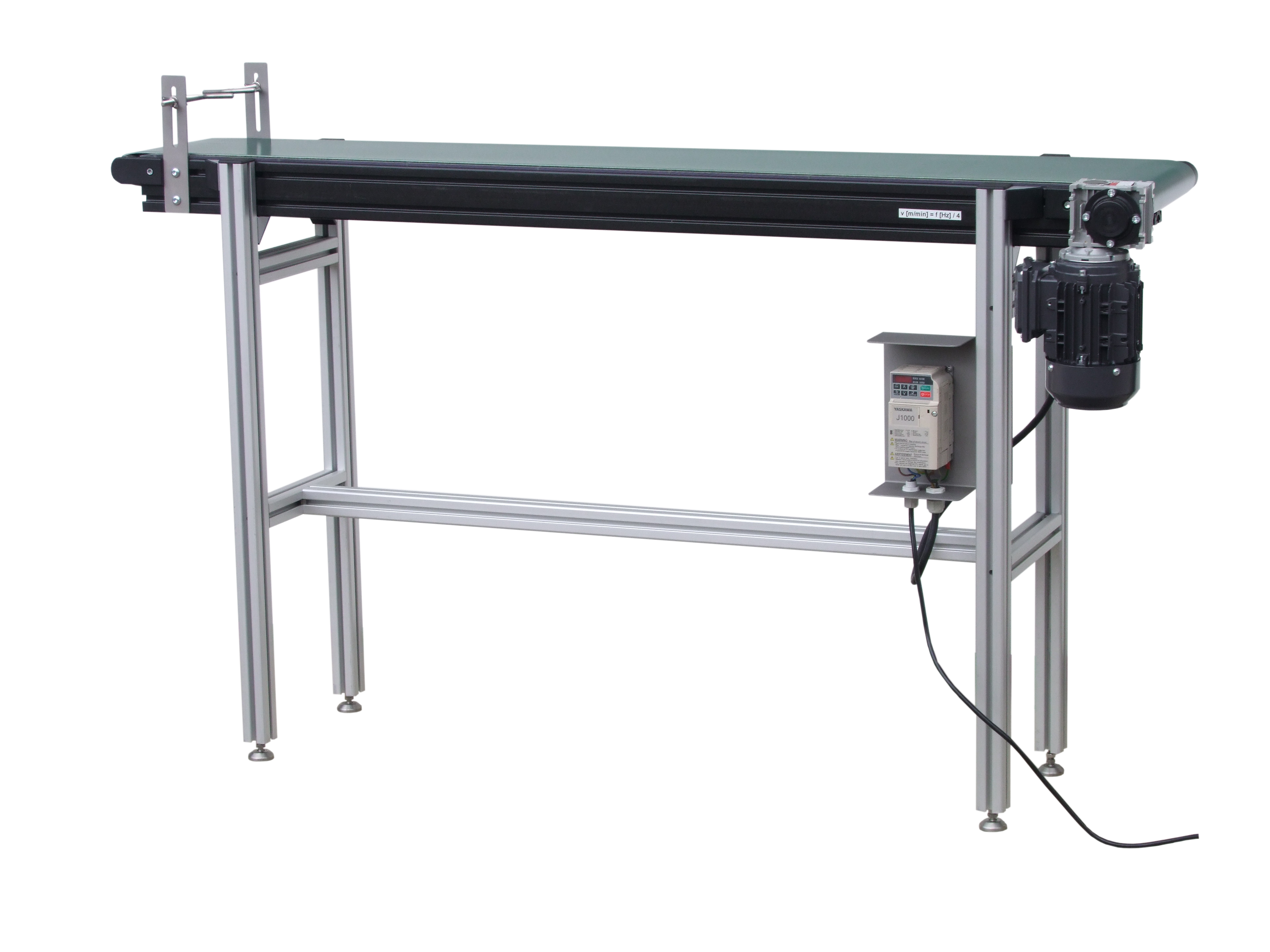

By placing the heating head right above the bottles that are being carried by the conveyor belt we get an continuous, highly efficient technology and production line.

Areas of application include but are not limited to the following:

- Food industry (ketchup, mustard, honey, horse radish, syrups, jams, ice cream)

- Dietary supplements (vitamins, body building supplements, energy supplement)

- Pharmaceuticals (vitamins, medicines, human analyser reagents)

- Veterinary (vitamins, medicines, dietary supplements)

- Cosmetics (skin care, nail care materials, perfumes)

- Chemistry (pesticides, paints, cleaning materials)

- Auto industry (motor oils, windshield wiping fluids, car care materials)

- Other fields (e.g. fish foods, shisha materials)

Productivity is determined by the following factors:

- Raw materials of the bottle

- Size and design of the mouth of the bottle

- Size, shape and material of cap

- Heating head design

- Power input

- Speed of conveyor

Bottle materials suitable for induction cap sealing:

- PET

- PP

- PE, HDPE, LDPE, MDPE

- glass

| Sealing foils and liners | IC-5 Induction Capsealer | Special conveyors for capsealers |

|

|

|